Custom made tailored resins

- Surfaces with multi-functional groups

- Binding cavities with coordinated functional groups

Selectivity principles are based on complementary multi-functional affinity surfaces and cooperative binding, either as multi-functional binding surfaces or as advanced constructed binding site cavities, to exihibit heightened affinity and selecitivity for the desired target compound.

Temiz examples resin, microscopic picture.

Average size ca 500 µm.

SEM example of large pores. Magnification 50.000 x

Multi-functional surface

Multi-functional resins display 2 or more distinct chemical surface functionalities. Those exhibit surface binding interactions with the desired target molecules. Multi-functional surfaces offer increased selectivity and/or affinity performance towards target molecules.

The chemical groups can be designed and synthesized in discussion with the customer.

Constructed cavity site

Constructed cavity resins contain accessible binding sites that entail synergistic functional groups that cooperate to bind a target molecule. Cooperative interactions are expected to exhibit a higher selectivity and/or affinity performance towards target molecules.

The chemical groups and their positions can be designed and synthesized in discussion with the customer.

Examples of application compounds

Difficult separations are for example the removal of toxic or unwanted contaminants from natural biological extracts or synthetic mixtures, or biotechnological process solutions.

Natural unwanted compounds can be all types of positively, neutral or negatively charged compounds. An example of unwanted non-natural compounds are agricultural or industrial residues such as pesticides or other chemicals.

Retrieving target compounds from very difficult mixtures is a main application area. Examples are biopharmaceutical or fermentation broths, cell culture solutions, or plant extracts

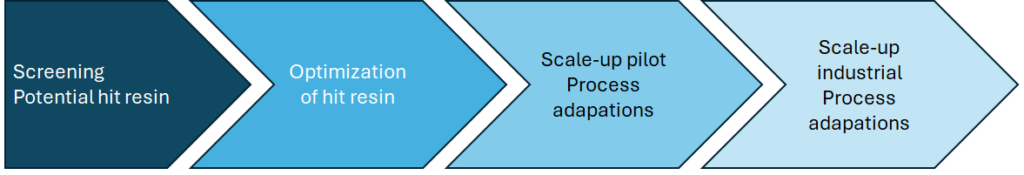

Steps of tailor-made resin development

Depending on the separation challenge, first in-house “one-functionality” resins can be used, or more advanced multi-functional resins or highly engineered constructed cavity resins can be synthesized and evaluated.

A typical resin development project for a purification problem will go through the standard project phases with defined goals and gates to go to the next phase.

For project start, customer sends samples of material to be purified to Redstone Separations AB in Sweden.

- In-house library screening for first resin hits / or de-novo synthesis of new resin designs

- Optimization of hit resins for further performance

- Optimization of resin synthesis at lab scale

- Scale-up to pilot scale

- Scale-up of optimized resin to commercial / industrial scale

Redstone can deliver tailor made resin to customer and supports resin testing or implementation after each stage.

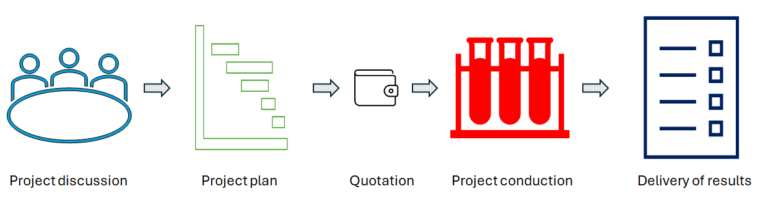

Project planning & conduction

Please contact us for further discussion as this is a case-by-case evaluation.

We will present a project plan and a quote.

Email: info@redstone-sep.com

Phone: +46-738-156-130 (Call times during CET: 8.00 – 18.00)